HEPA filter & UVC filtration? Or a choice of one or the other?

The Covid-19 peak appears to have passed and whilst there may be subsequent outbreaks we are encouraged to return to work and to reopen the economy.

This has prompted employers across the country to investigate measures to make the work places safer. The purity of the air circulating around building ventilation systems and delivered into occupied spaces is now understood to be an important aspect of workplaces safety. Here we take a closer look at the choice between retrofitting HEPA filter and UVC to building ventilation systems, or to use one of the other of the technologies to ensure that air supplied into occupied spaces is safer.

Understanding Existing Filtration Capability

In choosing between HEPA filter & UVC in the quest to make buildings safer from Covid-19 it is worth firstly understanding how effective how effective the existing filters in a system are against the virus.

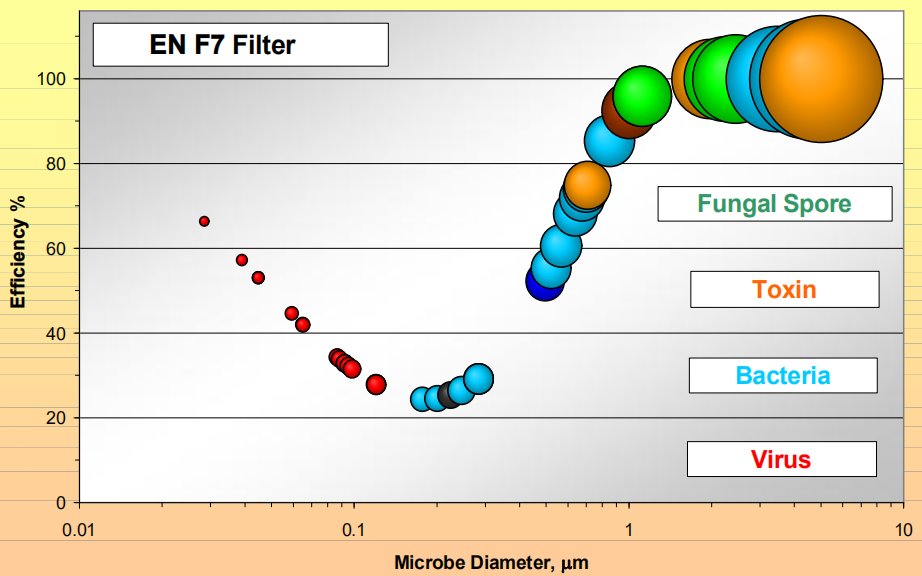

Mechanical ventilation systems that process the air supplied to, and extracted from, occupied spaces have typically been designed and installed with at the very least some filtration to protect the heating and cooling coils and the fan from dust accumulation. Often the filters will be a combination of a panel type prefilter, perhaps G3 or G4 efficiency followed by a F7 efficiency filter.

The size of the virus Covid-19 is widely accepted as being 0.12 microns, and looking at the graph you will notice that this size is in keeping with the larger size viruses (red dots) and that with F7 filters you could reasonably expect to remove around 25%. Worth also noting that even with F7 filters you can expect some relatively high filtration efficiencies against larger micro organisms, particularly fungal spores.

Better efficiency filtration in air handling unit will go further than this and offer in the case of F9 filters, capture efficiency of over 95% of PM2.5. This goes a huge way to protecting building occupants from lung damaging dust, airborne spores, and bacteria. Viruses however are of a much smaller scale and typically less than 0.2 microns. Although fine filters such as F9 grade will catch some particulates of this size, the efficiency of fine filters of this type are not tested and rated against this scale of challenge.

The HEPA Filtration Solution

HEPA filters are tested against what is known as the MPPS (the most penetrating particle size). MPPS is generally accepted as being 0.3 microns and is the most difficult size to catch. The efficiency of HEPA filters at catching the MPPS depends on grade. With H13 being the lowest grade of HEPA having 99.95% or better efficiency up to H14 grade having 99.995% efficiency. These efficiencies are tested and easily demonstrable.

So if we know that the new bank of HEPA filters fitted in the AHU will catch 99.95% of the most penetrating particles, i.e. the MPPS (0.3 micron) we can be certain that the efficiency of catching Covid-19 (0.12 micron) will be higher because the efficiency at particle sizes smaller than the MPPS are greater.

HEPA filter pleated media

The filtration performance of HEPAs is not in doubt as the standards to which they are manufactured and tested are rigorous. However ensuring that the installation of the HEPA filters in the air handling unit has the seal integrity to ensure that the performance suggested by filter class is maintained, is far more problematical.

The problem areas are inevitably the seal between the HEPA filter and its holding frame, the seal between one holding frame and adjacent holding frames, and the seals between the outer perimeter of the holding frames and the skins of the AHU. Ensuring these seals are air tight and that there are no holes to allow 0.12 micron size particles to slip through is a challenge not to be underestimated.

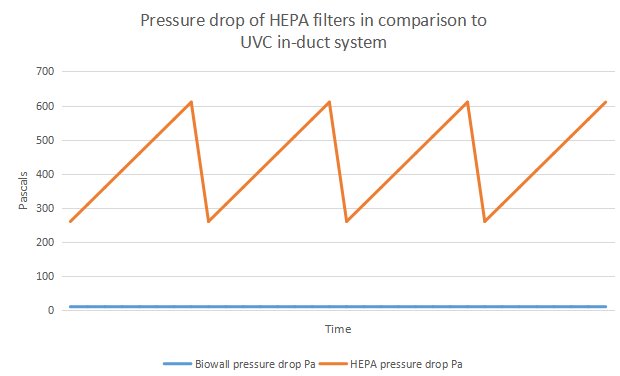

Achieving the HEPA filter and holding frame is not the only installation issue. The pressure drop that a HEPA filter stage in the air handling unit will add to the overall system will be considerable and in order to retain the same airflow through the ducting system to the occupied spaces, it is certain that the fan will need to be run at a higher speed or it will require modification (replacement pulleys and belts) or changing for one that can accommodate the additional pressure from the HEPA filters.

Once the fans have been altered or changed to suit this additional 600 Pascals of pressure (recommended change pressure for most HEPAs), the true cost of this increased level of filtration becomes apparent by the big increase in the running costs due to the increase in energy used by the fan.

UVC in duct fitting

The UVC Solution

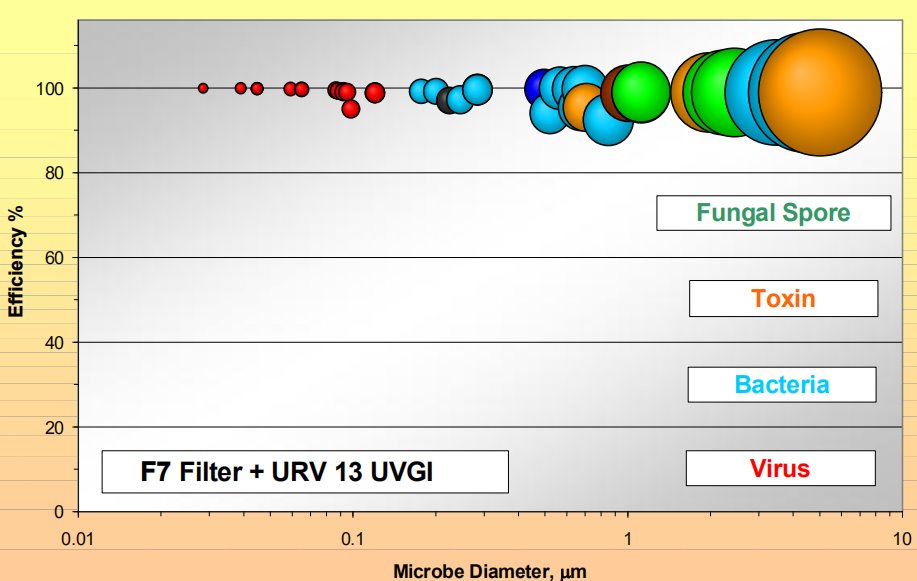

UVC does not catch micro organisms like Covid-19 virus like HEPAs do. But it can, if properly designed, deactivate micro organisms to efficiency levels comparable with the capturing efficiency of HEPA filters. But the problem is proving it. Whilst it is easy to measure particles in an air stream and test HEPAs, the same luxury of testing is not economically available to UVC. Instead for UVC the proof of efficiency is in the maths.

It is widely accepted that the quantity of UVC energy required to achieve a certain percentile deactivation of micro organisms is known. Tables containing UVC dosage for different micro organisms are always being refined and updated as new ones are identified. This information together with information about UVC intensity from lamps and the parabolic reflectors in which they are held forms the base information to a mathematical modeling program

For each application we add the site specific parameters including duct size, airflow, temperature and the specific target organism (which these days is typically covid-19). An in duct UVC product selection is made and the % efficiency of deactivation on 1st pass and subsequent passes is calculated. The maths is complex and even takes into consideration the material of the ducting as the different reflectivity of different materials has a quantifiable effect of on the efficiency of the UVC fixture in the application.

In duct UVC fixtures are normally installed down stream of the air handling unit, so they work in combination with the existing fine filters that are in the air handling unit. The effect is that the limited removal efficiency of the F7, F8, or F9 filters is complimented by the very high deactivation efficiency of the UVC array.

HEPA filter & UVC. A Comparison

HEPA filter

UVC air purification

What does it do?

Catches particles including micro organisms and inert but never the less harmful particles such as soot particles. In other words filters are broad spectrum and bring wider benefit than just catching viruses.

Deactivates airborne micro organisms including viruses, spores, and bacteria. When sized and designed for one target organism it will by default have increased efficiency on all those micro organisms requiring a lesser UVC dose and decreasing levels of efficiency on those requiring a larger UVC dose.

How efficient is it?

By EN1822 standard against MPPS a... H13 filter will be over 99.95% efficient H14 filter will be over 99.995% efficient

Induct UVC array can be sized and specified per application to achieve over 99.95% deactivation on covid-19 and if required can be specified to as high as 99.995% deactivation.

Provable performance?

Provable by EN testing standards.

Provable by standard UVC micro organism deactivation dosage information and application/product specific modeling.

Installation

Holding frames installed into AHU. The effective sealing of frames to skin of AHU is critical to ensure overall efficiency of installation is as close as possible to the efficiency of the HEPA filters put in the frames. Integrity of the seal between the HEPA filter and the holding frames also important. Additional pressure resistance from HEPA filters particularly when dirty will necessitate either modifications to, or change of the fan(s).

In duct UVC array is very quick and easy to install. It is installed ideally in the supply duct down stream of the AHU where it can benefit from relatively clean air afforded by the fine filters protecting the coils. The array is mounted on a pair of struts that span the inside of the duct so that the UVC array sits central in the air stream and parallel to it. The array is connected to a control panel that contains the ballasts that power the lamps.

The running cost to a bank of HEPA filters comes from; a. the periodic filter changes that will be required. b. the pressure drop range of around 200- 600Pa though the life of the HEPA will cause increased energy use and of cost.

The running cost to an induct UVC array comes from: a. the periodic lamp changes that will be made ever 2 years or so. b. the power to the array of lamps (about 260w) will cause a modest increase in the cost of treating the airflow. However there is almost no pressure drop burden to affect the power consumption of the fan.

Advantages

Catches inert particulate matter as well as micro organisms so wider scope of benefits to building occupants

- Fraction of the running cost compared to a bank of HEPAs. When factoring filter changes, lamp change, it is typically only 15-25% of the cost of running HEPAS

- Very easy to fit in ducting

Disadvantages

- Expensive, costly and fiddly to install as more work needed for holding frames, seals and fan modifications

- Might not be space in AHU to accommodate a bank of HEPA filters

- Costly to run

- UVC does not catch particles. It only deactivates biological particles

- Care needs to be taken if installing in air handling units to protect plastics within AHU from direct UVC light and to have door interlocks to prevent direct sight of UVC in operation

HEPA filter & UVC used in combination

Using both in combination is the ultimate in belt and braces approach.

If you put the UVC array upstream of the HEPA filters then the effect is to disable the micro organisms before catching them in HEPA filters. To put the UCV array after the HEPA filters is basically using the UVC to deactivate the very small portion of micro organisms that pass through the HEPA (in the order of 0.1 - 0.01%)

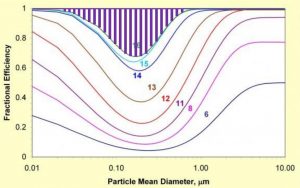

The graph (left) shows fractional efficiency of MERV (Minimum Efficiency Reported Value) rated filters. Although this does not correlate directly to HEPA filters It does serve to demonstrate the dip in efficiency at the MPPS. The same dip happens for HEPA filters but to a lesser degree and it is micro organism particles represented by this gap (the hatched area) that UVC downstream of a HEPA would be deactivating .

HEPA filter & UVC filtration - Consider the purpose

If the purpose of the modifications to the air handling system is to make the supplied air safer from airborne micro organisms and if with the existing fine filtration (F7, F8, or F9) in an air handling unit, together with a properly specified UVC induct array can achieve an efficiency of at least 99.9% against Covid-19 then the thorny question has to be asked;

- What is the point of adding an additional cost of HEPA filters, their installation and their heavy running cost?

But equally, if the purpose of the modifications to the air handling system is to make the supplied air safer from all particles including inert sub micron size particles, then;

- What is the point of adding an additional cost of a UVC array if the micro organisms they are trying to deactivate have already been caught up stream or will be caught in HEPAs downstream?

HEPA filter & UVC filtration used in combination in mobile air cleaners

It is worth mentioning that there is a trend for portable/mobile air cleaner units that have both HEPA filter and UVC. These tend to follow a well trodden path originally set by the domestic air cleaner world which is that is that 'features' sell. 'HEPA' is regarded as a feature, as is 'UVC' and they are seen by the unwary market as 'must have's.

In the Covid-19 world, given that the objective of both of these is the same in that you are looking to reduce the quantity of viable aireborne coronavirus particles, then is strange to demand that an air cleaner must have both features. The problem is that many of these type of units have token gesture HEPA filters and token gesture UVC. In other words the filter and its holding frame can be untested, full of holes and unsealed to the air cleaner body, whilst the UVC is likely to be pitifully inadequate to treat the air flow to any credible level of efficiency. There are however exceptions. We have scoured the market and added a range of credible air purifiers from Sodeca to our line up. This range has been recently developed and seems to avoid the glaring design errors that plague the vast majority of products in the sector.

HEPA filter & UVC - A Summary

- There is no clear winner between the two because they both have merits and ideal applications, indeed they can even be used in combination if there is a need to fill the efficiency gap in the HEPAs inherent weak point i.e, at the MPPS.

- The HEPA filter solution catches all particles to understood levels of efficiency but that 'catch all' capability comes at an eye watering running cost and more often than not a significant complexity and costs to the retrofit.

- In duct UVC arrays deactivate biological particles ensuring they are incapable of replication, in other words rendering them inert and the running cost is limited to running the lamps and replacing them every 2 years. They are a doddle to retrofit into ducting and require no fan upgrading.