Industrial Air Purifiers

Background to the StaticAir Industrial air purifiers

There is a lot of pressure to ensure that workplaces have clean air. Under pressure from occupational health regulations and a general duty of care, employers need to be able to demonstrate that they are compliant with current regulations. But it's not just people who require clean air. Maintaining clean air state is beneficial for many industrial processes, raw materials, components, and finished goods.

The standard solution to cleaning air used to be an air cleaner and a standard air cleaner was an arrangement of a fan and some filters in a box. Dirty air in one side - filtered air out the other. So old hat.

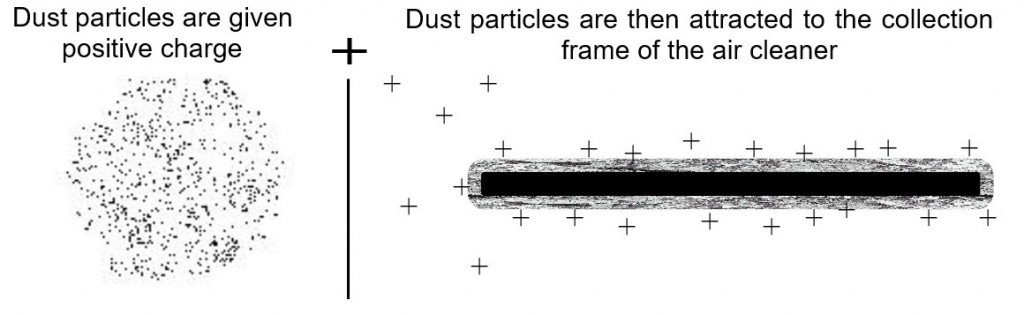

In the domestic environment there have always been ionisers. These where not air cleaners in the normal sense, and did not have a fan and filter but they did produce lot of ions that charged dust particles, which helped to encourage the dust with a charge to stick to surfaces. They worked to an extent.

New design for industrial air purifiers by StaticAir

StaticAir has a new and fascinating take on industrial air purifiers. Taking the basic principle of the domestic ioniser and applying some serious engineering and scaling up, it has developed a range of industrial air purifiers. These industrial air purifiers are a very capable new entrant to the market place for big air cleaners for big places.

What makes them brilliant is the lack of fan. In fact these industrial air purifiers are all solid state. No moving parts.

Part of the process is to discharge ions onto the air in huge quantities. The other part of the process is to have a collector surface of opposite charge to the charged dust particles, to attract them. Now this is similar to conventional electrostatic air cleaners that have a fan which creates an air flow. But as mentioned earlier - there is no fan.

Introducing Ionic Wind

Let me take you on a diversion. You may remember ionic propulsion as being a science fiction notion to propel space ships. Well it might be handy for space ships but it also has an application on planet earth. Air cleaners. When ions are produced by a ioniser and there is an opposite charge surface near by, the ions transfer from one to the other. This create a flow of ions on one direction. Ions attach to particles and in their own right and when attached to particles, their flow from one surface to another induces air movement. This air movement created by a flow of ions has broken new ground recently by being the means of propulsion for the first aeroplane to be driven by solid state electrics. Just think about it - a plane with no moving parts that can sustain itself in flight using ionic wind for propulsion. Search for 'ionic wind plane' in YouTube and see for yourself.

How it works in a nutshell

By creating a huge quantity of ions with the ioniser wires and having the other components either neutral or oppositely charged to the ions, a constant stream of charged particles is drawn to the unit.

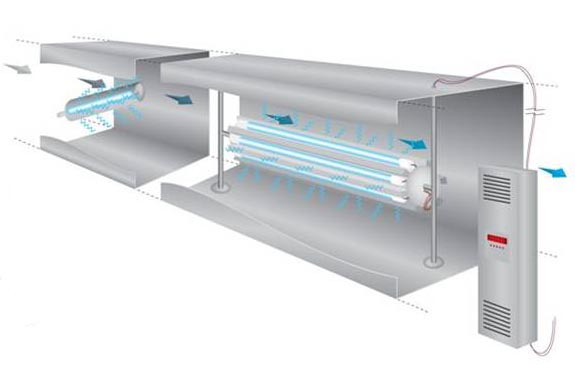

The ionic wind enters the air cleaner between a pair of the gills on the unit turns and is discharged via the two adjacent slots.

By turning the ionic wind in this way the charged particles are inclined to move towards the collector surface of the air cleaner both by centrifugal force and also by opposite charge attraction of the collector plates.

What makes StaticAir industrial air purifiers so effective?

With traditional air cleaners using filter technology the smallest, most harmful particles are the hardest to remove from the airstream. Of course there are air cleaners with HEPA filters of various grades that can catch the smallest particles but they are not only expensive to replace but it is also expensive to run the air cleaner fan to push the air through them. That running cost increases as the filter gets more laden with dust.

The brilliant thing about StaticAir industrial air purifiers is that they are at their best and most effective on the particle size range that is most challenging and expensive for conventional air cleaners. Removing the most harmful particles i.e. fine particles below 2.5 micrometers in size, is where the StaticAir units are so effective.

All the while they are working at removing dust particles, they are only consuming a miniscule 18 watts per air cleaner. Even better news is that they don't use air filters so there is no ongoing burden of replacing filter.

The StaticAir industrial air purifier range.

Where are StaticAir industrial air purifiers used?

Perhaps the most obvious application is industrial workspaces such as those found in the metal working and wood working sectors. Welding fumes, fugitive dust grinding and surface finishing are all suitable challenges. Oil mist and smoke from metal milling and hot surface treatments are best treated with Trion electrostatic air cleaners. But if the dust is a dry dust then StaticAir industrial air purifiers are an excellent choice. But these air purifiers have far wider application than just industry. They are also used in...

- livestock buildings particularly poultry sheds.

- outdoor street environments to reduce ambient concentrations of diesel soot particles from traffic

- waste processing environments

- primary industries such as quarrying, and stone processing

- leisure sector particularly gyms where chalk is used.

- indoor car parks

- road and rail tunnels

If you would like help with finding the ideal industrial air purifiers solution to your application get in touch 01729 824108