Mobile Evaporative Cooler Options

Mobile Evaporative Cooler Options.

In this article we discuss how evaporative coolers work and investigate which of the products on the market are suited to various applications. Traditional split type Air Conditioning machines recycle cooled air within a sealed or semi-sealed environment as allowing cooled air to escape would drastically reduce the efficiency of the process. The heat is transferred to a recirculating liquid which then passes through a heat exchanger outside the building and is dispersed externally.

On the other hand Evaporative Coolers are particularly suited to environments which for one reason or another cannot be sealed or where there is a preference for 'Fresh' air rather than recycled air.

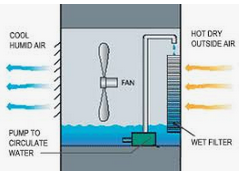

The simplified diagrams show how the process works. Fresh air is drawn in from outside the building and passed through a recirculating 'curtain' of water (the wet filter). A proportion of the cascading water evaporates into the air stream providing cooling in the same way as sweating cools humans and animals.

The remaining cascading water absorbs an exactly equivalent amount of heat from the air. As a result the properties of the air stream are converted from warm/dry to cool/moist.

Exhaust exits MUST be provided on both fixed and mobile Evaporative Cooling Systems in order to prevent the build up of moisture within the building.

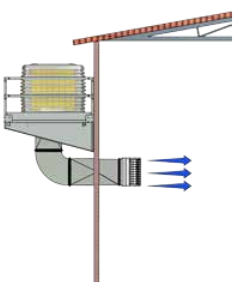

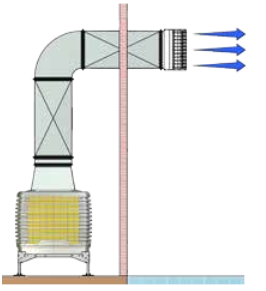

Fixed Evaporative Coolers

Fixed Evaporative Coolers would be permanently plumbed to the water supply and might be situated as per the illustrations below. These show a small number of a wide variety of possible configurations. Internally the cooled air is then ducted to the areas required. These systems draw fresh air from OUTSIDE the building and exhaust humid air from ventilation points around the building.

A Mobile Evaporative Industrial Cooler draws fresh air from INSIDE the building but humid air must still be exhausted from the building via ventilation points such as windows or open doors. A Mobile Evaporative Cooler will generally have a water tank incorporated rather than being plumbed in to a water supply.

Depending on the design it may be possible to attach a temporarily water supply via a level control system or more usually manual top up of the water tank is required. The DuraCool Mobile Evaporative Cooler has a 30 litre tank and will effectively serve an area of up to 50m2.

The CCX4.0 Mobile Evaporative Cooler for example has a 50 litre water tank incorporated into its base and would be manually topped up with water (hose pipe or the like). This will effectively serve an area of up to 80m2.

Mid-Range Mobile Evaporative Cooler

Met Mann's mid-size range of Mobile Evaporative Cooler are manufactured in Spain and are cleverly designed with features to make operation and maintenance easy. Made with the same tough components and superior build quality that are found in fixed units.

These Mobile Evaporative Coolers carry a 10 year guarantee for the polyamide top and base, whilst the other components are guaranteed for 2 years.

These Mobile Evaporative Coolers are designed to be a tough long-term asset. Equipped with automatic water tank level control the range offers throughput of 4,200 m3/h through to 15,000 m3/h in 5 sizes most of which are available in either fixed speed of inverter drive options. Weights range from 120kg through to 220kg at the top of the range. All units are supplied with a 25m hose so that the onboard water tank may be connected to the nearest tap/hosetail. Available in 1-Phase and 3-Phase alternatives they are ideal for Large Commercial and Small Industrial applications.

Moving up again in size we near the practical limit for a Mobile Evaporative Cooler. Master's range includes the BC180 and BC340. The Master BC340 Mobile Evaporative Cooler covers an area of 400m2 and also has automatic water tank level control. At peak output the Master BC340 consumes 15-20 litres of water depending on the ambient temperature and relative humidity of the incoming air.

Having a tank volume of 200 litres it will need topping up only once per 10 hours of continuous peak output. Even so it consumes only 1.1kW of power and so will operate off a single phase, 13 Amp plug. Ideal applications include Workshops, Warehouses and Manufacturing units as well as Greenhouses and Cowsheds.

Help and advice

If you would like to find out more or to get advice on reaching an ideal air circulation system for your application then email us at [email protected] or call us on +44 (0)1729 824108