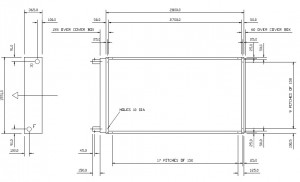

Cased LPHW heater battery with spigot connectors

A standard LPHW heater battery

LPHW Heater Battery: Overview

The applications for a low pressure hot water LPHW heater battery are varied. Sometimes they are fitted into ducts that handle general ventilation air for occupied spaces to elevate air temperature to a ‘comfort’ level. In other applications are to do with ‘process air’ in which the temperature of the air flow has a bearing on the outcome of a production process or perhaps a drying process, for example drying grain or biomass fuel.

In either case the principles of selection for a LPHW heater battery are the same…

- Step. Quantify the basic physical parameters. This will include hard details such as duct size, but also the more variable details such as airflow, ‘air on’ temperature and relative humidity and the available LPHW temperature and flow. Also it is good to know what pressure capability there is in the fan; the model of fan and where is currently operating on its ‘fan curve’ will let us know what further performance we can get with the existing fan.

- Step. Quantify the desired outcome. This may include an ‘air off’ temperature but is more likely to be a temperature range. Alternatively, it may be a space heating requirement that requires ‘X’ kw in order to heat the space from one temperature to another, and to hold it there, in which case the LPHW heater battery has to be able to deliver that kw output on the airflow available and the actual air off temperature is a secondary consideration.

- Step. Is a LPHW heater battery in this application feasible? Sometimes, achieving the desired outcome from the physical parameters is either just not possible, or, it is possible but at disproportionate cost. If this is the case we need to consider other heating methods, eg electricity, steam.

- Step. Assuming it is feasible with a LPHW heater battery, investigate if there are any other factors that will affect design. This may include airborne dust, explosion risks (ATEX), airborne chemical contaminants etc.

- Step. Work out the performance requirement from the LPHW heater battery, i.e. kw output for the inlet air condition envelope and the LPHW flow and temperature.

- Step. Select a suitable product to match the performance requirement. Bare in mind the pressure capability of the fan, ducting type, transition ducts, ducting connections, LPHW connections etc. Also consider controls, e.g. duct thermostat, actuated valves, bypasses etc.

In many cases this can be standard product, but if the duct size, airflow or heating requirement is beyond the scope of standard LPHW heater batteries, or if the air is dusty or corrosive then look to get the heater battery made to order at the ideal size, fin pitch and or of suitably resistant materials.

If it is not on the shelf, get it made.

The process of specifying and selecting a LPHW heater battery may appear a long process, but it is within the Puravent range of capability.