Trion Electrostatic Air Cleaners - Background

With a very long history the market for industrial air cleaning, Trion have an unmatched expertise in producing industrial electrostatic air cleaners that are suited to the most difficult air cleaning challenges. As Hoover is to the vacuum cleaner, Trion is to industrial electrostatic air filtration.

Trion started business in 1947 and since then many thousands of their electrostatic air cleaners have been installed in industrial and commercial applications across the globe. Puravent have been supplying Trion electrostatic air cleaners for over 15 years. In that time we have built up quite an attachment to the company and their electrostatic air cleaners.

Our liking for the Trion air cleaner range is based principally on Trion's capability, the equipment's construction, components, features, their durability and their availability of spare parts.

Electrostatic Air Cleaners - Terminology

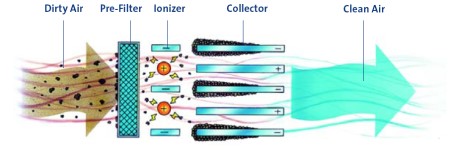

As often called electrostatic precipitators as electrostatic air cleaners, in fact both terms are correct. Sometimes they are called electrostatic air purifiers, and although they are electrostatic, they are not air purifiers. Air purifiers are a completely different group of products which we cover in detail in other pages on this site.

Trion Electrostatic Air Cleaners - Capability

For any air cleaning machine it is as important to know what it can't do as well as what it can do, because to have units in use on marginal applications is a problem in the making. With such a long history in the field Trion have a very detailed and clear knowledge of their electrostatic air cleaners and the thousands of different air-borne challenges that they can be used for. Type of contaminants, airflow, temperature, humidity and both the physical and environmental constraints of an application all have a bearing on the type of equipment and model of electrostatic air cleaner that we recommend. Trion's depth of technical backup added to our own technical capabilities and knowledge ensures that we get it right first time, where other potential solution providers may either propose an ineffective or inappropriate system or one engineered to short life and limited performance.

Trion T Series Electrostatic Air Cleaners - Construction

The principle range of the Trion electrostatic air cleaners is the T series. The range follows a modular construction which uses common key components across the range. Units are given a 'handing' at the factory to determine the airflow direction through the unit, which provides versatility on access arrangements for maintenance and also enables units to be back to backed to double the capacity. Flange bolting patterns are identical for inlet and outlet so that the units are easily connected in series for enhanced performance, and so fabrication of inlet and outlet transformer ducts are the same.

All units in the T series range have the capability for drainage to be connected and on larger configurations drains can be arranged direct unit to unit and from the lowest unit to a collection vessel or sump. The units are all made with tough painted steel sheet casings to provide superior protection to the inner components.

Inside each Trion T Series unit is the electrostatic collector cell, which has ioniser and collector plates built into an easy pull out unit which is robust and designed for prolonged service life.

Electrostatic Air Cleaners - Components

With a long experience of electrostatic filters in use, Trion are very knowledgeable on critical components and spare parts. This means that their history has taught them how to engineer and manufacture components in order to ensure that the units don't fail from under engineered key parts.

|  |

For example, other electrostatic air cleaners can easily and quickly fail from simple problems like cracked isolators, broken or worn ionisers. In contrast Trion units have a uniquely large stepped ceramic isolators, which are out of the airflow and which increase the distance of isolation between oppositely charged components (to eliminate 'tracking') and are far more resistant to cracking. Likewise the ionisers are spiked plate design which not only last much longer in service than the ioniser wires of other systems, but are also far more resistant to mechanical damage either from cleaning.

Features That Make It A Trion

Sometimes its the little things that make the difference. To mention some examples;

- T series electrostatics with fans have blowers that are fully enclosed, making them dramatically more resistant to damage from dirt and oil impregnation

- VOMP 600 has special isolators that induce clean air to pass over the surfaces of the insulator to ensure that it is kept clean to ensure long life

- Trion collector cells are manufactured with extra depth in the plate. This ensures both higher efficiency and higher contaminate holding capacity

- Series 60 and 120 electrostaic air cleaners have ARC suppression power supplies, which ensure that cracking noise is minimised. Although not vital in noisy industrial settings, this feature is useful in service and leisure sectors

- Many Trion electrostatic air cleaners can be easily connected into building management systems so that they can be remotely controlled and, or, interlinked with the operation of machines.

- Trion T series electrostatic air cleaners can be fitted with eye bolts for suspending from other structures

- T series electrostatic air cleaners can be fitted to a carbon filter odour reduction unit

Trion Durability and Spares

Nothing lasts forever, but some things last a good deal longer than others. Industrial and commercial electrostatic air cleaners are no different to any other machine and Trion electrostatic filters excel at lasting a long time. Testament to this are the notable absence of spare part enquiries for newer machines and only occasional enquiries for spare parts to fit units which are sometimes several decades old. Because Trion keep good records we can generally identify and supply the correct part for any of Trion's commercial or industrial electrostatic filters.

Larger Trion Systems

There is a limit to the air cleaning applications that can be solved using the 'off the shelf' Trion products. For larger air flows and for those with more demanding types and levels of contaminants, sometimes more complex systems are required. Although generally assembled from a kit of pre-designed standard components, the bigger electrostatic air cleaner systems like Trion Model 60 and Model 75 may have any number of the following elements;

- Fan

- Autowash system

- Fire Suppression system

- Impinger

- Media Filter

- Carbon Filter

- Detergent tank

Trion Model 60 electostatic air cleaner. 12990 - 53420m3/hr |  Trion Model 75 electrostic air cleaner with autowash. 2140 - 45890m3/hr |

Standard Trion Electrostatic Models

The Trion range includes the following models;

Electrostatic air cleaners for oil mist removal and recovery of oil mist within pipes or enclosures;

Electrostatic Air cleaners for fugitive airborne contaminants;

Trion T1300 electrostatic air cleaner and blower. Upto 2210 M3/Hr |  Trion T2600 electrostatic air cleaner and blower. Upto 4420 M3/Hr | Trion T5002 electrostatic air cleaner and fan. Upto 8840 m3/hr |

Electrostatic Air Cleaners for ducted air flows with oil mist, grease droplets and smoke;

Electrostatic air cleaners for ceiling mounting

Trion Air Cleaner - Series 60 air cleaner. 340 - 680 m3/hr |  Trion Series 120 ceiling mounted air cleaner and smoke eliminator. 680 - 1360 m3/hr |  Trion Spacesaver ceiling mounted air cleaner. 680 - 1000 m3/hr |

Electrostatic Air Cleaners for small commercial and domestic ducted air cleaning applications

Trion HE Plus 1400 duct mounted electrostatic air cleaner. 900 - 1400 m3/hr |  Trion HE Plus 2000 duct mounted electrostatic air cleaner. 1800 - 3600 m3/hr |