Antares E

The filters of the ANTARES line represent the most modern and effective solution to the problems of suction and filtration of oily vapours and fumes generated from the use of cooling lubricants (emulsions and whole oils) used in all types of work centres (CNC) and of tool machines generally. They are designed according to the criteria of modern technology, they are intended for the industrial sectors that need easily installable suction and filtration equipment that is compact and which offers high levels of reliability and robustness. The ANTARES line filters have been designed to be applied vertically above the tool machine. The ANTARES filters are made of carbon steel air tight-welded sheet metal which is oven-coated. They are equipped with pre-drilled coupling flange to be attached directly to the tool machine.

The "user interface" signalling electronics are created using LED technology.

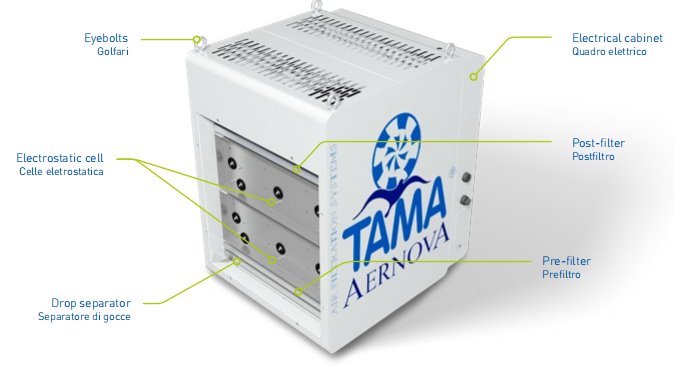

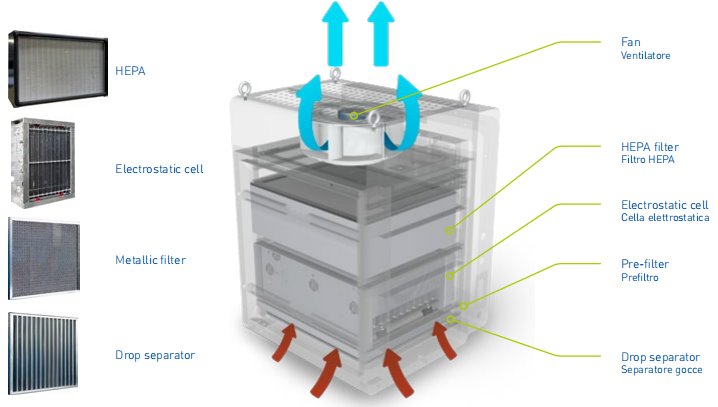

The ANTARES E are small electrostatic air cleaners specifically designed for removing oil mist from the enclosures of milling machines and laths The ANTARES E electrostatic air cleaners have a pre-drilled rectangular inlet opening which enables it to be mounted directly to the milling machine or laths enclosure. The air is pulled through the unit by the fan located on the top of the air cleaner and this puts the whole enclosure under a negative pressure

The intake air charged with oily pollutant passes through the drop separator where the "droplets" of oil present in the airflow are separated and retained. The air then passes through a mechanical pre-filter which has the function of diffusing the air uniformly before the electrostatic filtration. The air then passes through the electrostatic filter which consists of an ionising section and a collecting section.

IONISING SECTION

The ionising section consists of overlapping sheets with the interposition of "ionising" wires made of tungsten. The ionising wires are supplied with a voltage of 8.5 KV and are used to generate an electrostatic field to yield positive charges to the particles of the flow of polluted air.

COLLECTOR SECTION

The electrostatically charged particles pass through the collecting section that consists of overlapping plates charged with a voltage of 4.5 KV. The particles are then held in the collecting section with the "grounded” plates.

The TANDEM versions are fitted with a further electrostatic cell to improve the separation efficiency in the presence of high concentrations (greater than 40mg/Nm3).

After the electrostatic filtration is the post-filter that like the prefilter, helps to retain the airflow distribution through the collector section. The versions with HEPA filter guarantee the best separation efficiency available.

| Model | Filters | Filter area | Maximum air flow (free air) | Working air flow | voltage | power | |

| Electro static cells |

HEPA H13 | m2 | m3/hr | m3/hr | v | watts | |

| ANTARES 200 E1 | 1 | N/A | 4.12 | 1200 | 900 | 230 | 190 |

| ANTARES 200 E2 | 2 | N/A | 8.25 | 1200 | 900 | 230 | 190 |

| ANTARES 200 E1 A | 1 | 1 | 4.12 | 1200 | 900 | 230 | 190 |

| ANTARES 200 E2 A | 2 | 1 | 8.25 | 1200 | 900 | 230 | 190 |

| ANTARES 300 E1 | 1 | N/A | 5.63 | 1500 | 1300 | 230 | 190 |

| ANTARES 300 E2 | 2 | N/A | 11.26 | 1500 | 1300 | 230 | 190 |

| ANTARES 300 E1 A | 1 | 1 | 5.63 | 1500 | 1300 | 230 | 250 |

| ANTARES 300 E2 A | 2 | 1 | 11.26 | 1500 | 1300 | 230 | 250 |

| ANTARES 400 E1 | 1 | N/A | 14.69 | 2000 | 1650 | 230 | 400 |

| ANTARES 400 E1 A | 1 | 1 | 14.69 | 2000 | 1650 | 230 | 400 |

This range is not available via our website although we can supply this products in this range to suit specific applications.

For pricing and help please enquire using the 'Enquire for Price' button, or call us on 01729 824 108.

| Delivery | This item is normally assembled to order in mainland Europe and delivered direct |

|---|---|

| Brand | Purified Air |

| Warranty | 1 year warrenty in compliance with ORGALIME S2000 |