Trotec TTR 2400 2400 m3/hr Desiccant Dryer

The TTR 2400 comes from the Trotec TTR range of silica wheel based adsorption dryers. This technology is used where very low level humidity is required and where there is a critical requirement to retain humidity at an exact level. In these type of applications compressor based dehumidifiers are considered inadequate and only well engineered adsorption dehumidifiers can be considered.

The electronically-controlled dehumidification units in the TTR Series are ideal for these demanding applications and guarantee a constantly high dehumidification capacity. The TTR drying units are also optionally available as a hire model with a stackable steel frame and crane eyes and fork lift slots for locations that have to be changed frequently. The housing to the units consists thermally and acoustically insulated galvanized steel panels which have been given a protective coating. The bodywork of the TTR series is also optionally available in stainless steel.

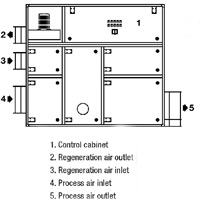

The main dehumidification unit, a reliable silica gel adorption rotor in washable and mechanically high-tensile design, as well as further components like fans, air filters, regeneration heaters or electrical components are protected against unauthorized use by lockable service flaps. Regeneration of the rotor uses an integrated heat recycling feature which results in more efficient energy use in the regeneration cycle.

• Robust high quality units manufactured in Germany.

• Process air quantity 2,400 m³ / h at 300 Pa pressure

• High dehumidification performance also at low temperatures

• Reliable silica gel adsorption rotor in washable and mechanically high-tensile finish

• Integrated heat recycling

• Electrical regeneration heating

• Double-walled, galvanized construction with heavy-duty finishing

• Stainless steel housing available as option

• Protective galvanized outer frame available as an option

Applications

This type of dehumidification plays a vital role in retaining the value of machines, inventory and buildings. Using these machines in preventative maintenance can avoid the effects of corrosion or other moisture damage to protective coatings or reinforcements. A permanent guarantee of unchanging internal climatic conditions, above all in sensitive areas and processes, particularly in the handling of powdered materials e.g. in the food or pharmaceutical industries, place the highest demands on the quality and reliability of the drying units that are employed. Adsorption dryers are also found in the production, transport or storage sectors where continuous and reliable air and gas dehumidification is an absolute necessity for countless processes.

• Dehumidification of unheated rooms, e.g. in water technical facilities and pump stations to prevent the formation of condensate on pipes, storage tanks and pumps

• Prevention of corrosion in electrical control centers, boiler plants, turbines and pipe systems in power plants

• Constant guarantee of low relative humidity in industrial production facilities and storerooms, for example in the food, dairy or pharmaceutical industry

• Corrosion protection for ships in control and machine rooms as well as moisture sensitive loads in transit

• Prevention of corrosion in fuel depots or ships’ holds in connection with sandblasting or painting work.

Other models not shown here are available - call us for details 0845 688012

| Title | Value |

|---|---|

| Process air flow rate | 2,400 m³/h |

| Process air pressure | 300 Pa |

| Process air dehumidification | 14.4 kg/h |

| Regeneration air flow rate | 620 m³/h |

| Regeneration air pressure | 400 Pa |

| Voltage | 3 x 400 V |

| Mains frequency | 50 Hz |

| Total power usage | 23.6 kW |

| Delivery | Dependant on stock availability. Check with us before ordering |

|---|---|

| Brand | Trotec |

| Warranty | 1 year manufacturers warranty |